Analysis example

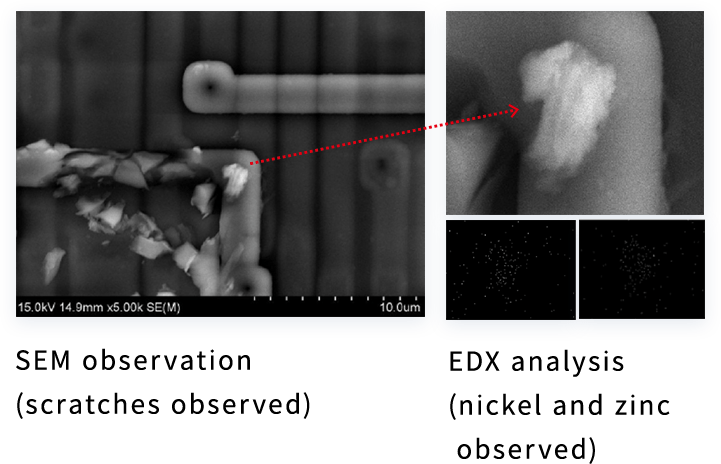

[Case 1]

Defect phenomenon: IC malfunction

- Analysis result

-

- The malfunction was found to be due to scratches on the IC surface.

- Nickel and zinc, which are not chip constituent materials, were detected in deposits near the scratches, suggesting that the scratches were caused by contact with metal.

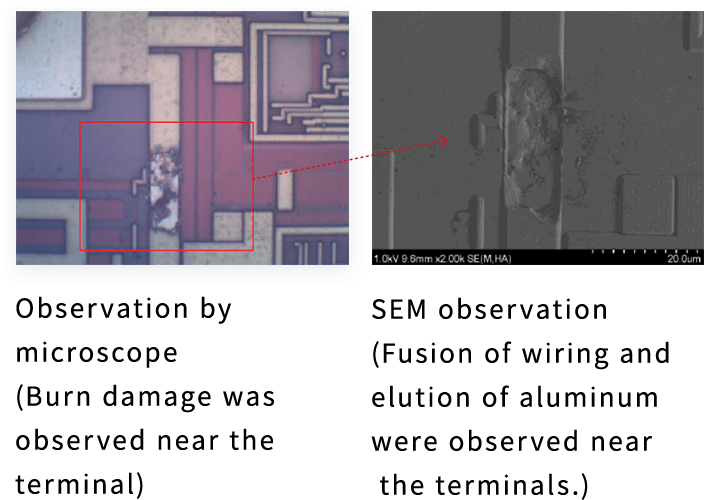

[Case 2]

Defect phenomenon: Oscillation failure

- Analysis result

-

- The cause of the oscillation failure was found to be an opening due to melted wiring.

- The cause of the melting is presumed to be reverse insertion of the IC or overvoltage/overcurrent (EOS: Electrical Over Stress) destruction due to overcurrent to the terminal.

In order to achieve quality that satisfies our customers, we show the process from planning, development, production to shipping and collaboration with each other.

We evaluate the suitability of quality and reliability designs by reliability testing based on accumulated reliability data.

Semiconductor products are easily affected by the surrounding environment, so please handle and store them with sufficient care.

Introduces the in-house analysis system and analysis examples for identifying the location of failures and cause of defects.

Process information from production, processing, inspection, and shipping of products is recorded by lot number, which makes searching and tracking possible.

Aiming to harmonize with the global environment, we are working to reduce harmful chemical substances contained in our products, including our supply chain.