Environmental Policy

- Basic philosophy

- Seiko NPC aims at corporate activities and growth in comformity with its environment. Through developing, manufacturing and selling semiconductor products, Seiko NPC contributes to realize sustainable recycling-oriented society which reduces burden on the earth, so that we can continue to live together with natural environment.

- Action policy

-

- Seiko NPC not only observes laws and regulations but also pays close attention to and copes exactly with environmental trends and movements.

- Seiko NPC promotes to realize recycling-oriented society by effectively applying environmental management system.

- Seiko NPC not only makes efforts to reduce burden on environment, but also continues activities on valuing and saving limited energy and resources.

- Seiko NPC challenges to develop innovative technologies and products which realize recyling-oriented society.

- Seiko NPC makes positive efforts to collaborate and cooperate with stakeholders on environmental problems, as well as improving awareness of its employees through in-house training and education.

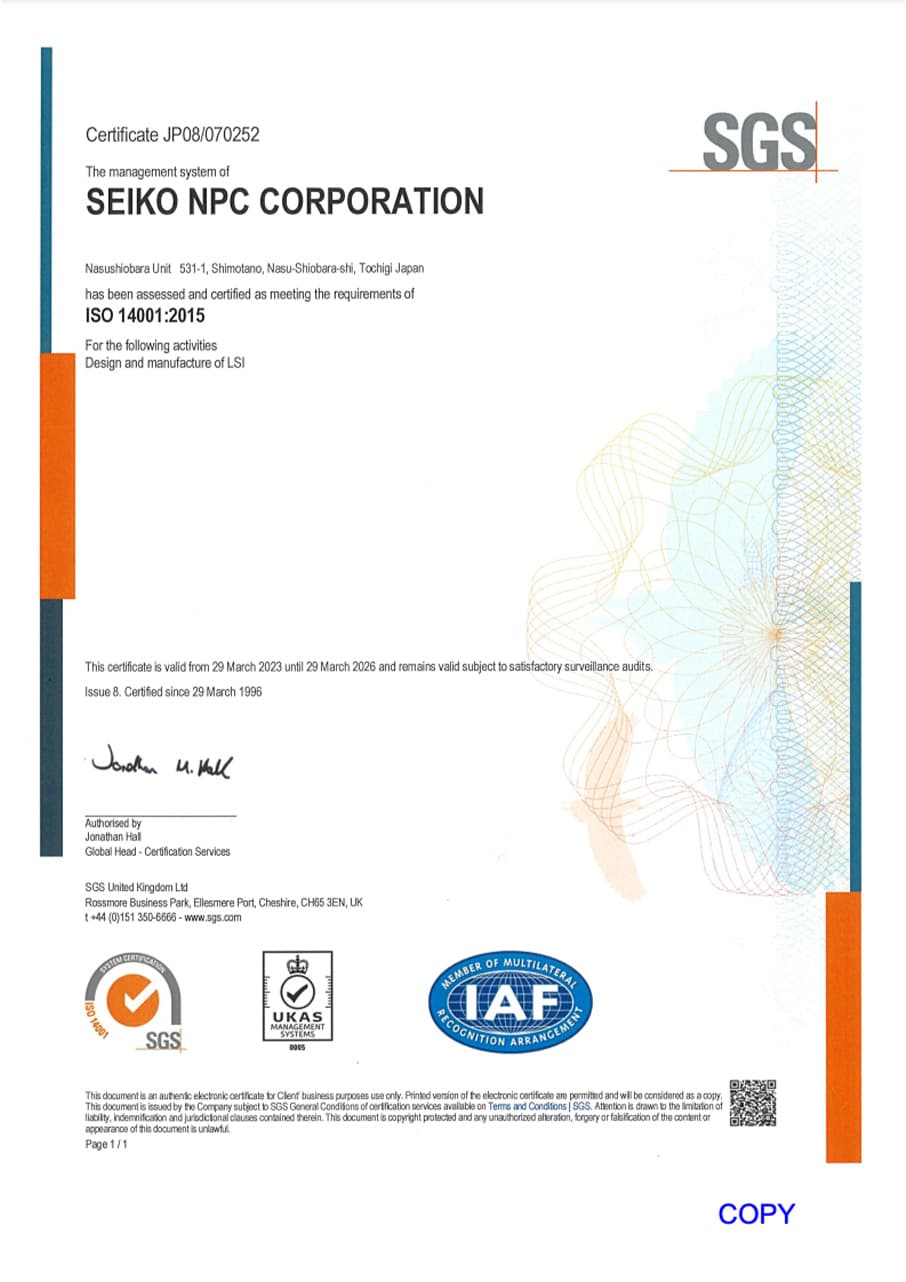

- ISO14001

-

Seiko NPC acquired ISO14001 certification in March 1996.

<Scope of application>

Applicable office:Seiko NPC Corporation Nasushiobara Unit

Applicable organization:Applies to all people working at the Nasushiobara Unit.

Applicable business:Applies to environmental conservation activities related to plant site, buildings and equipment used for LSI design, manufacturing, service and business.

First registration date:

March 29, 1996Issuance date:

March 29, 2023Expiration date:

March 29, 2026Certification body:

SGSCertificate

No.JP08/070252